FLUID CLEANLINESS STANDARDS

For the control measures of the contamination, it is necessary to realize the level of cleanliness of a fluid. The "ISO code index numbers" can never be increased with the increase of particle sizes. For example: "18/20/22". The distribution of all particle has smaller as compared to larger particles.

So, a "contamination reference scale" is being utilized to identify and address issues. To develop standards for cleanliness level, the most widely recognized method of particle counting is used. Delicate optical instruments are utilized to compute the digits of particles that range in various size. These calculations and considerations are accounted as the digit of particles more important than determining the size that is found in a predefined volume of liquid.

The cleanliness level standards of "international Standard Organization (ISO 4406:1999)" has achieved wide recognition in various organizations today. According to these standard references, in an identified volume, the quantity of particle that is greater than 4, 6, and 14 micrometres are generally 1 millilitre or it can be 100 millilitres. The digits of 4+ as well as 6+ micrometre, particles are utilized as a source of perspective point, for "silt" particles. The range of size 14+ shows that the number of higher particles are present, which contribute incredibly towards the failure of the conceivable catastrophic component.

An ISO classification of 19/16/13 can be defined as:

Fluid Cleanliness Standards

REQUIREMENTS FOR COMPONENT CLEANLINESS LEVEL:

Many industrialists who are involved in hydraulic and load-bearing equipment, they have specified the most favourable cleanliness level that is essential for their gears. Exposing components to liquid may have resulted in a considerably shorter life of component if the contamination level is high.

The following table shows some common components and their standards of cleanliness levels. In every case, it is best to talk with the function designer and to get their written recommendations regarding fluid cleanliness level. For selecting a suitable filtration level, these recommendations are required.

It is also proved valuable for any kind of ensuing warranty claims, as it can help to differentiate between standard uses and extreme or offensive procedures.

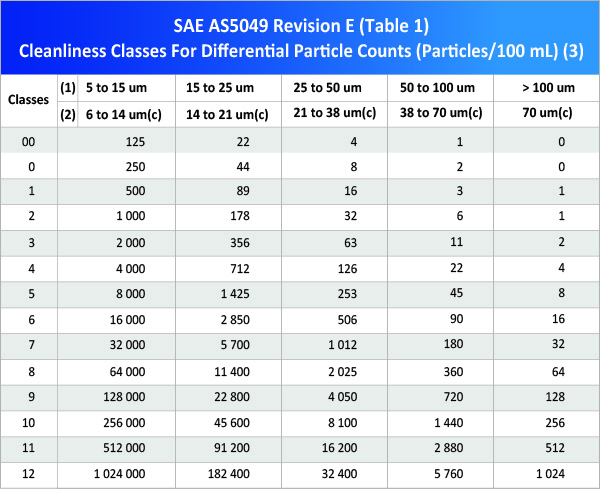

SAE AS5049 Revision E (Table 1)

Cleanliness Classes For Differential Particle Counts (Particles/100 mL) (3)

(1) Size Range, Optical Microscope, given the longest measurement as estimated per ARP598, APC Calibrated per ISO 4402:1991.

(2) Size Range, APC Calibrated per ISO 11171 or Electron Microscope, given anticipated territory identical distance across.

(3) Classes and defilement limits indistinguishable from NAS 1638.